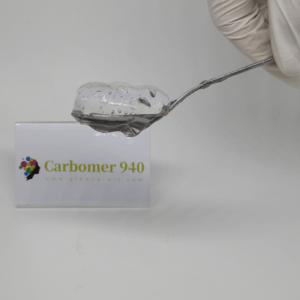

The gel prepared with carbomer as an auxiliary material is a transparent semi-solid, uniform texture, and has the characteristics of a water-soluble matrix. It can be coated on the skin and mucous membranes to form a transparent film with strong adhesion.

1.1 Water-Soluble Gel

Usually, when preparing water-soluble gels, the first step is to fully swell the carbomer in the solvent. First wet the carbomer with water, ethanol, glycerin, or propylene glycol, to avoid dust flying, and then gradually add water to swell; you can also sprinkle the dry carbomer powder on the water surface in batches and leave it overnight to make it fully swell and avoid caking; or under the high-speed stirring of the agitator, sprinkle the carbomer powder into the vortex formed by stirring, and continue stirring until it is completely dispersed in the solvent.

Step 2 is to add prescription drugs. First, slowly drip the neutralizer into the carbomer solution, stir it and make it into a gel, and then add the prescription drug to the gel matrix, grind the solution and get the finished product, or first add the prescription drug to the carbomer solution to make the drug dissolve or grind until it is uniformly dispersed, and then add the neutralizer and grind it.

1.2 Emulsion Gel

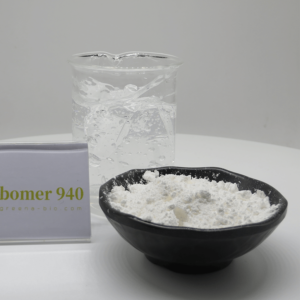

Carbomer is used as the gel matrix, water, glycerol, and ethanol are the water phase. Castor oil is the oil phase, polysorbate 80 is the emulsifier, and triethanolamine is the neutralizer. The specific preparation process is as follows: after fine grinding of glycerol and carbomer 940, adding a small amount of distilled water to fully dissolve and expand- phase A. Take castor oil and add triethanolamine and stir well to get phase B. Add phase B to phase A for grinding, and then add polysorbate 80 and continue to grind evenly (paste), finally slowly add ethanol and distilled water to the full amount, and continue to stir and grind into a latex. Emulsion gel can be made by this method without heating at room temperature.

Xi'an Greena Biotech Co.,Ltd. is the specialist in the natural products & chemical manufacturer.

Xi'an Greena Biotech Co.,Ltd. is the specialist in the natural products & chemical manufacturer.